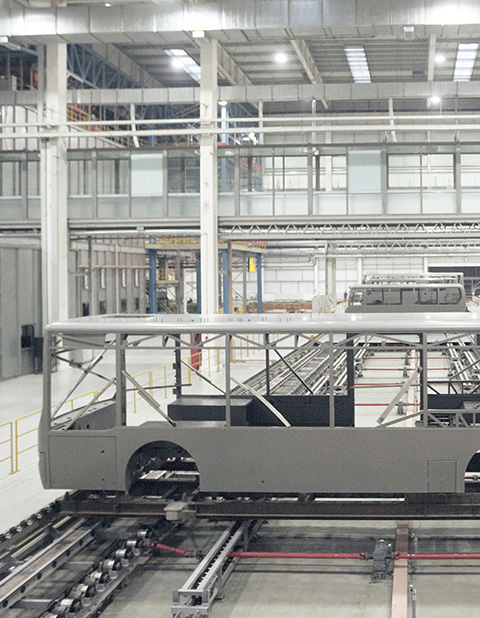

The Body Structure is Stable

and Reliable

-

45°

Equipped with a super-strength closed-ring structure, the vehicle rollover angle can be up to 45° with minor rollover deformation.

-

-10%

With lightweight technology, 10%-20% weight reduction is realized and over 10% energy consumption reduced.

-

-10%

With the optimized aerodynamic streamline structure, the vehicles achieve wind resistance and energy consumption reduced by 10% and 5% respectively.

-

+50%

Box structure enables the shear resistance of roof and body frames up 50%.

-

-3mm

The rectangular anti-collision beam structure reduces the maximum deformation of the side traction battery compartment anti-collision beam by about 3 mm.

Durable and Reliable Material

-

High-Strength Materials Enhance the Body Frame Strength and Vehicle Rigidity

High-Strength Materials Enhance the Body Frame Strength and Vehicle RigidityHigh-strength materials enhance the body frame strength and vehicle rigidity, thus improving the safety and reliability of vehicles.

-

The Front and Rear Walls Adopt Hot-Dip Galvanized Steel Panels

The Front and Rear Walls Adopt Hot-Dip Galvanized Steel PanelsThe front and rear walls adopt hot-dip galvanized steel panels, guaranteeing the flatness and strength of appearance, and solving the irreparable and ageing problems of the fiber reinforce plastic (FRP) front and rear wall panels.

-

The Bodyside and Top Cover Adopt Double-Sided Hot-Dip Galvanized Steel Panels with High Purity

The Bodyside and Top Cover Adopt Double-Sided Hot-Dip Galvanized Steel Panels with High PurityThe bodyside and top cover adopt double-sided hot-dip galvanized steel panels with high purity, good anti-sag and anti-rust performance, and high surface finish.

-

The Vehicle Doors Are Made of Aluminum Alloy

The Vehicle Doors Are Made of Aluminum AlloyThe vehicle doors are made of aluminum alloy, which is light, durable with strong anti-corrosion performance.

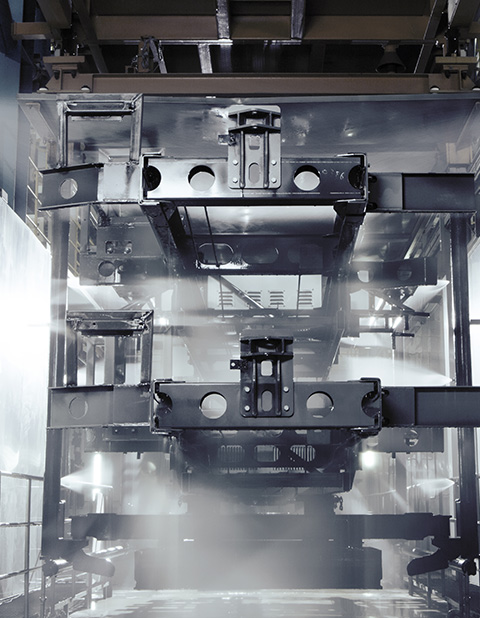

Application of Technical Processes

-

Argon mixed gas shielded welding ensures welding quality and avoids local failure expansion.

Argon mixed gas shielded welding ensures welding quality and avoids local failure expansion. -

The pipe and harness layout and design are based on the separation concept to reduce potential hazards and facilitate maintenance.

The pipe and harness layout and design are based on the separation concept to reduce potential hazards and facilitate maintenance. -

Electrical protection system guarantees the safety of vehicle harness.

Electrical protection system guarantees the safety of vehicle harness.

Subscribe Now

Get updates you care about.

Submit